We Don't Just Make Things. We Make Things Smarter, Faster and Better.

Globe Tech offers problem-solving partnerships for commercial manufacturing. Globe Tech’s engineering department integrates with customers to enhance designs and produce quality products.

FABRICATION/WELDING/PROTOTYPING

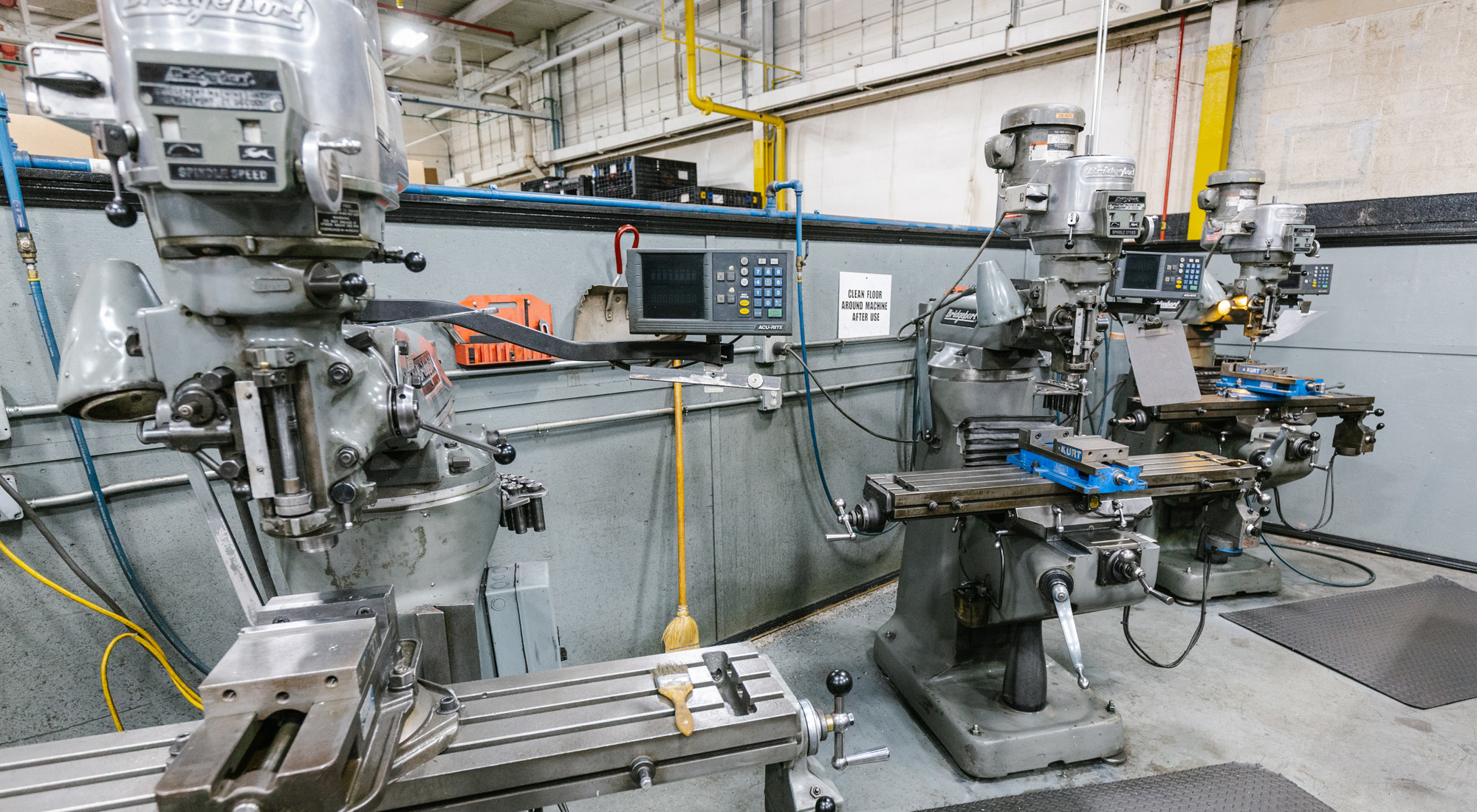

Our fabrication team has the capabilities to process materials using laser, plasma, and waterjet. We are skilled in CNC machining, rapid prototyping, forming and bending, robotic and manual

certified welding, and certified weld repair.

- Robotic and Manual Metal Inert Gas (MIG)

- Projection

- Resistance

- Tungsten Inert Gas (TIG)

- Certified Weld Instructor

- Press Brake (350T)

Welding Capabilities

Certified welders in-house

Robotic and manual welding

- Titanium

- Aluminum

- Steel

- Armor

- GMAW

- GTAW

ASNT QUALIFIED LEVEL 1 & 2 TECHNICIANS ON STAFF

- MT

- PT

- UT

Product Design

- 3D Modeling

- NX UG

- Catia

- Solid Works

- VAVE Studies

- Plastic Printed Prototypes

- Reverse Engineering

Validation

- FEA – Cosmos & Nastran

- Simulation – Auto Form

- Physical Testing

- White Light Scanning

Facility highlights

- 180,000 sq. ft. of facility space

- 150,000 sq. ft. of manufacturing space

- 4 overhead bridge cranes from 5-40 ton

- 12 Jib cranes 0.5- 3 ton

- High-speed Machining Center

- CNC Lathes

- Vertical Mills

- Plasma Cutter Machine

- Gibson Sand Blaster

- Flow Water Jet

- Easy access to all major expressways

Differentiators

Certifications

A2LA Certified Lab

Certified WBENC

(Women’s Business Enterprise)

WOSB

(Women Owned Small Business)

CWI On-Staff

(Certified Weld Inspectors)

Cage: 4QK42

DUNS: 195217661

IATF 16949:2016

(Scope: Assembly, Metal Stamping, Riveting, Welding)

ISO 9001:2015

(Scope: Assembly, Die Design, Machining, Metal Stamping, Plasma Cutter & Waterjet, Welding)

ISO 14001:2015

(Scope: Design and manufacture of prototype and production dies and manufacture of metal stamping and welded assemblies)

AS9100D

(Scope: Machining, assembly and manual welding of defense related product, excluding prototypes)

Responsive and Flexible

Globe Tech has dedicated the past two decades to maintaining only the highest quality and safety standards. The company will continue to invest in new technologies to maintain a competitive edge to meet customers’ timing and quality demands.

Program & Project Execution

Globe Tech has experience in effective project execution under tight timelines and an inconsistent source availability. We support internal operations of our clients by addressing existing deficiencies, such as flawed technical data packages or assembly processes.

The Right Infrastructure

Globe Tech is conveniently located off of I-275 and within 30 miles of Detroit Arsenal / United States Army Tank-Automotive and Armaments Command (TACOM) centers.

Relationships

Sponsorships and Support