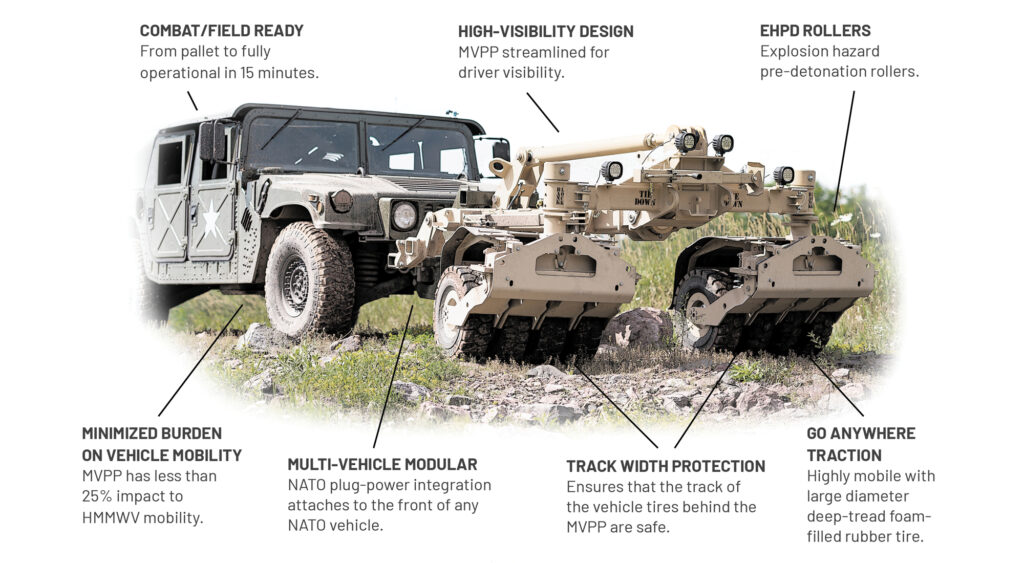

MVPP

Modular Vehicle Protection Platform

HIGH VALUE.

HIGH PERFORMANCE.

Innovative design compatible with JLTVs and HMMWVs

- Multi-vehicle Modular

- Cost and Time Effective

- Highly Maneuverable

- Fast In-field Install

- Combat Ready

DESIGN | ENGINEERING - MVPP OVERVIEW

- Track width protection

- Base mechanical pressure plate & tilt rod threat protection (surface and buried threat emplacement) with modular capacity to include additional threat protection capabilities (adjustable coverage area, wire neutralization, active down force application, thermal, magnetic and acoustic threat protection)

- Platform design to also accept detection capabilities (auxiliary hydraulic & electrical supply options available)

- Highly maneuverable with 360 castored wheel banks with no loss of forward/reverse operation or vehicle turning radius. Minimal impact turning envelope

- Highly mobile with large diameter tires with deep tread and spoil mitigation

- Hard, sharp corner carcass, foam-filled rubber tire provides significant effective width and threat plate impact load but allows terrain conformity for improved effectiveness and minimal vibration detriment to system

- Tires provide significant cut, tear, and abrasion resistance

- Foam-filled rubber tires display good high-temperature thermal resistance during long-term high-speed operation on paved roads in high-temperature environment

- Vehicle integration provisions for standard US Army 3-point interface and specialized 3-point JLTV interface (JLTV integration also allows 300-pound weight reduction through removal of interface to interface (121) frame)

- Inline fused standard NATO plug power integration for lighting on base configuration and for hydraulic power unit (HPU) on upgraded configurations

- NATO standard tie down and lift provisions provided

- Fits onto US standard 463L shipping pallet for air drop deployment

- Vehicle integration from pallet to fully operational system (assuming vehicle interface already integrated) within 15 minutes

- Less than 25% mobility impact to 3265 kg (7,200 pound) HMMWV

-

Significant obstacle negotiation capabilities

- 18 inch Vertical Step

- Large, Deep V Negotiation

- 40% Paved Longitudinal Grade

- 30% Unpaved Longitudinal Grade

- 5% Soft Soil Longitudinal Grade)

- 30% Unpaved Lateral Grade (Side Slope)

- Large Rock & Non-Orthogonal Log Traverse

- 30% Sharp Grade Approach & Departure

- 16 kph (10 mph) 20 cm (8 inch) half round impacts

- Straight line and unrutted turning operations on flat/level soft soil terrain - Significant non-uniform terrain following at speed (12 inch lateral ruts and 4 inch longitudinal RMS @ elevated speed (12 mph - vehicle limited) with significant roll freedom at both bank and cross beam

- Good driver visibility

- Durable (insert op mode for primary, secondary, trail, cross country operations)

- Highly effective, 90% (+) pressure plate threat initiation for common architecture, sub surface emplaced IED triggers at typical clearance speeds 6 & 9 kph (10 & 15 mph)

- Significant (60 lb sub-surface threat at outboard bank wheel) blast protection with substantial system survivability

- Significant anti-rotation due to blast protection provided by inclusion of upper and lower push frames

- Lighting kit (visible & infrared) for nighttime operations

MVPP PERFORMANCE HIGHLIGHTS

Differentiators

Certifications

A2LA Certified Lab

Certified WBENC

(Women’s Business Enterprise)

WOSB

(Women Owned Small Business)

CWI On-Staff

(Certified Weld Inspectors)

Cage: 4QK42

DUNS: 195217661

IATF 16949:2016

(Scope: Assembly, Metal Stamping, Riveting, Welding)

ISO 9001:2015

(Scope: Assembly, Die Design, Machining, Metal Stamping, Plasma Cutter & Waterjet, Welding)

ISO 14001:2015

(Scope: Design and manufacture of prototype and production dies and manufacture of metal stamping and welded assemblies)

AS9100D

(Scope: Machining, assembly and manual welding of defense related product, excluding prototypes)

Responsive and Flexible

Globe Tech has dedicated the past two decades to maintaining only the highest quality and safety standards. The company will continue to invest in new technologies to maintain a competitive edge to meet customers’ timing and quality demands.

Program & Project Execution

Globe Tech has experience in effective project execution under tight timelines and an inconsistent source availability. We support internal operations of our clients by addressing existing deficiencies, such as flawed technical data packages or assembly processes.

The Right Infrastructure

Globe Tech is conveniently located off of I-275 and within 30 miles of Detroit Arsenal / United States Army Tank-Automotive and Armaments Command (TACOM) centers.

Relationships

Sponsorships and Support